Positive temperature coefficient (PTC) heating technology revolutionizes the capabilities of heating components in an array of applications. It delivers better performance, more reliable regulation, and uniform temperatures than other comparable heating technologies on the market today.

PTC materials are known for their high thermal stability, meaning they can maintain a consistent temperature even when subjected to variations in input power. These qualities make PTC heating technology ideal for many applications, including the following.

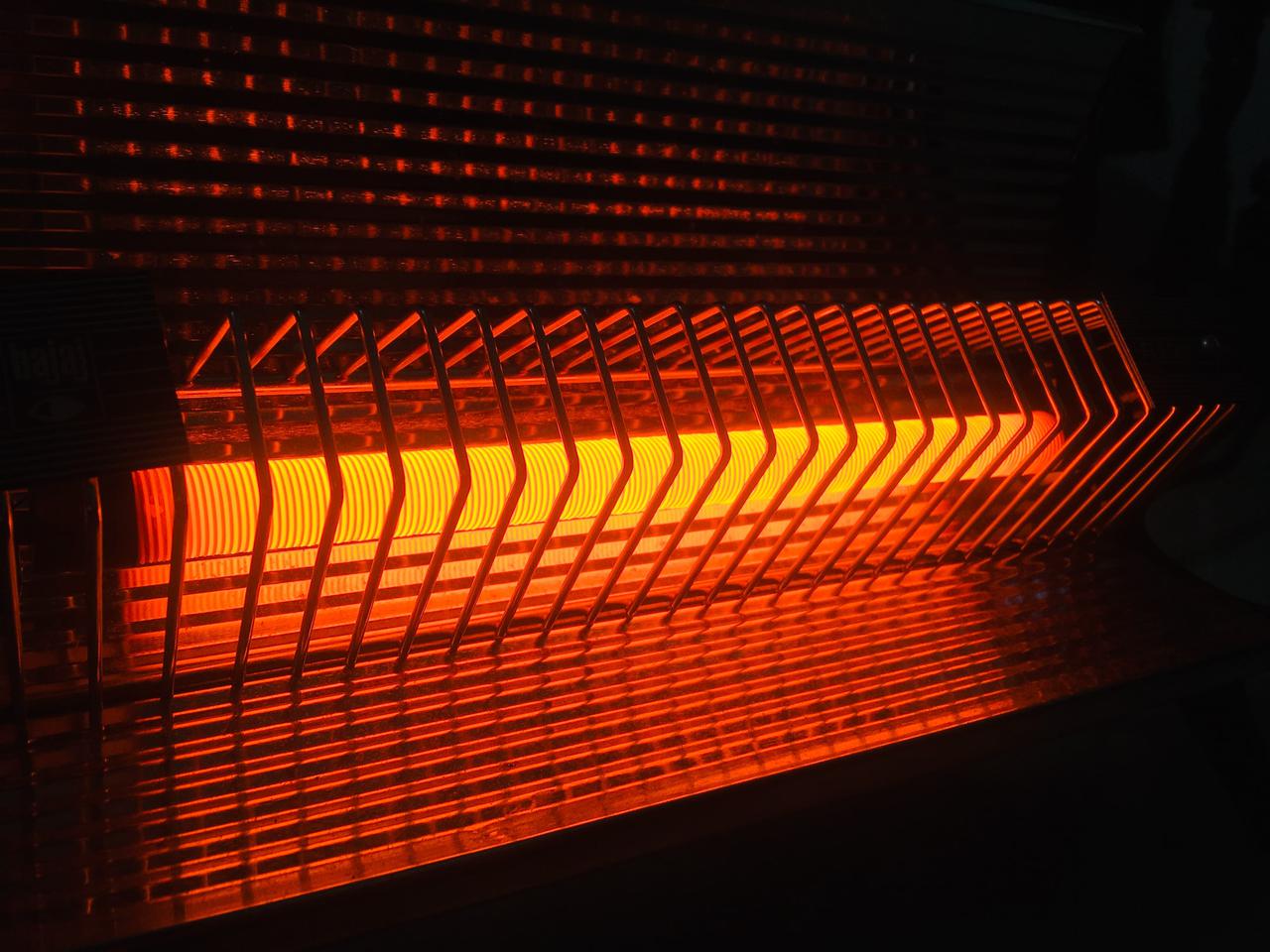

PTC technology uses electricity to convert heat into infrared energy. It’s often used in outdoor heaters, but the components can also be used for indoor appliances. Heating materials are known for their high efficiency and safety, making them a popular choice for space heaters. They also require less electricity to generate the same amount of output as metal wire heaters.

Heaters using these components will also last longer before needing to be replaced, delivering a higher-quality product to consumers. Finally, ceramics are more durable than other materials, making them less likely to break or malfunction.

It may surprise you that PTC technology is also used in heated clothing. This technology is deployed a little differently, delivering a safer and more durable option for heated clothing.

Heating technology is getting used more frequently in electric vehicles. It has properties that make it ideal for use in electrical insulation, such as being resistant to high temperatures and have excellent mechanical strength. PTC can help improve electric vehicle efficiency with better electrical insulation and thermal management.

PTC heating components can help to extend the life of electric vehicles by providing superior durability and resistance to wear and tear. As electric cars become more popular, PTC ceramic technology will likely become more prominent in their design and manufacturing.

PTC heating technology contains unique electrical properties that make it ideal for medical device applications. These materials can rapidly and reversibly change from electrically conducting to non-conducting when exposed to sudden temperature changes.

Medical devices using ceramic heater technology can safely disperse large amounts of power. They’re ideal for an array of applications, including those with high-voltage, such as:

This versatile new heating technology has the potential to revolutionize both devices and processes in the medical and health industries.

These are just the most popular current uses for PTC ceramic heating technology. It’s also being researched for future applications in solar energy systems, as it can convert sunlight into heat with unparalleled efficiency.

Switching from alternative heating components to PTC often improves a manufactured product’s quality, performance, reliability, and capabilities.

Delivering exceptional quality to your customers means sourcing the very best components available. Sisler Companies works with enterprises across industries to provide them with the parts and support they need to operate at the leading edge of their industry. We’re the warehousing, distribution, and sales representatives that managers count on as a partner to streamline and improve operations.

Whatever you need in your manufacturing and distribution organization, we’ll offer expertise, support, and advanced component services. Reach out to learn more about our range of services, including our patented PTC ceramic heating technology.