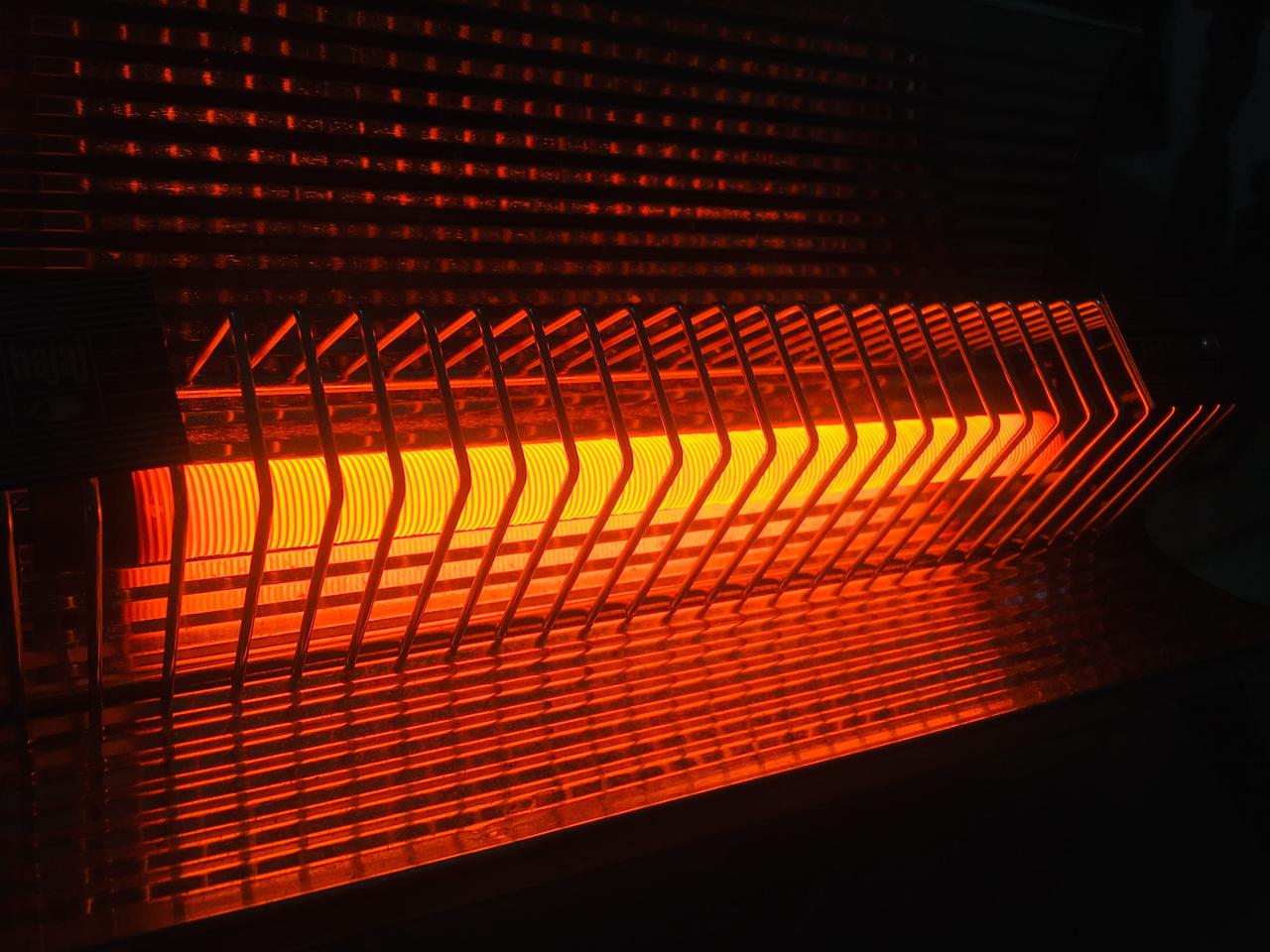

Have you heard about Positive Temperature Coefficient (PTC) heating elements and wondered, “why all the hype?” You’re likely familiar with the problems of traditional heating elements, such as overheating, low reliability, and unpredictable hot spots. You’re not alone if you’ve wondered why we use single-point sensors to dictate the temperature of the entire heater.

Despite the myriad annoyance, problems, and real safety concerns associated with traditional heating coils and elements, they remain standard across a vast range of industries and applications. New heating technology provides innovative solutions for the problems you encounter with conventional heating element products. You may not know these three things about PTC heating element products.

PTC heating elements are self-regulating and self-limiting, features that traditional heating elements don’t possess but are essential for making reliable and safe products. Single-sensor regulation assumes the temperature of the entire heater. While widely used, it's a system that can cause serious inefficiencies with the way your product heats, using more energy than necessary.

More than the expense and annoyance of inefficiency, it also presents a serious safety hazard. Overheating remains a common issue for traditional heating products. PTC heating element products are open-loop self-regulating so that they won’t overheat. The structure doesn’t use coils, or wires, like conventional heating. Instead, manufacturers print conductive inks on flexible substrates. It’s perfect for products that need efficiency and uniform heating. They’ll also be safer than if they’re built with traditional heating methods.

The conductive inks of PTC heating elements exhibit a positive resistance change when the temperature increases. As the air temperature rises, the PTC material limits the flow of the current through the component. As the temperature falls, the current flow increases, generating heat. This high-performance capability allows manufacturers to set target temperature zones between which the PTC heater functions.

While all PTC ceramic heating materials function best between -40°F and 158°F, skilled manufacturers can set a specific zone in which the heating product operates. PTC technology has advanced to where it’s possible to specify multiple thresholds for a single product to function within.

PTC heating element products also heat extremely fast initially. Waiting for products to heat when first turned on remains an ongoing concern and annoyance for consumers. PTC ceramic heating stones allow full current flow through the material, so they warm up fast and then self-regulate to maintain the temperature safely.

Overheating of traditional heating elements is one of the biggest safety concerns with heating products. It’s not an uncommon problem for conventional heating elements. Still, it’s just one issue that isn’t a concern for PTC heating element products. The technology is not only safer but also more cost-effective.

For unique heating products, PTC technology allows you to print custom designs on flexible materials. There are no limitations to the shape or structure of the conductive PTC inks, including cutouts and holes. You can customize the heating zones and adjust the wattage. There are simply more possibilities with PTC heating elements and the ability to create a far superior product than with traditional wire and coils.

Using a PTC heating element, you can manufacture a superior product that runs more efficiently and safer than with coils and wire while still more cost-effective.

PTC conductive inks are transforming the heating industry, opening up new possibilities and revolutionizing traditional heating methods. If you’re interested in the potential of this new technology for your product, reach out to a Sisler Company representative. We have manufacturing capabilities available for new business developments.

Contact us through our easy online form, or call 740-777-6560 to speak with our logistics experts directly.